Ethylene gas to tomatoes nyt: A journey into the intricate relationship between a ripening agent and the beloved fruit. Ethylene gas plays a pivotal role in the tomato ripening process, influencing its color, texture, and flavor. This article delves into the health implications, commercial applications, and ongoing research surrounding ethylene gas and tomato ripening, providing a comprehensive overview for readers seeking to unravel the complexities of this fascinating topic.

From the moment tomatoes are picked, a race against time begins as they embark on their journey toward ripeness. Ethylene gas acts as the catalyst, triggering a cascade of physiological and biochemical changes that transform the fruit from a firm, green orb into a vibrant, juicy delicacy.

Understanding the role of ethylene gas is not only crucial for tomato growers seeking optimal ripening conditions but also for consumers who desire the best-tasting tomatoes.

Health Implications of Ethylene Gas Exposure

Exposure to ethylene gas, a naturally occurring plant hormone, can have potential health implications, particularly in the context of tomato ripening. Inhaling ethylene gas can cause a range of adverse effects on human health, including respiratory irritation, nausea, and headaches.

Short-term exposure to high levels of ethylene gas can lead to acute respiratory symptoms such as coughing, wheezing, and shortness of breath. Prolonged or excessive exposure may result in more severe respiratory issues, including bronchitis and asthma. Additionally, ethylene gas can affect the central nervous system, causing dizziness, confusion, and even loss of consciousness in extreme cases.

Ethylene gas exerts its effects on the human body through various mechanisms. It binds to specific receptors in the respiratory tract, triggering a cascade of biochemical reactions that lead to inflammation and bronchoconstriction. Furthermore, ethylene gas can interfere with the body’s natural antioxidant defenses, making individuals more susceptible to oxidative stress and its associated health consequences.

Impact on Tomato Ripening

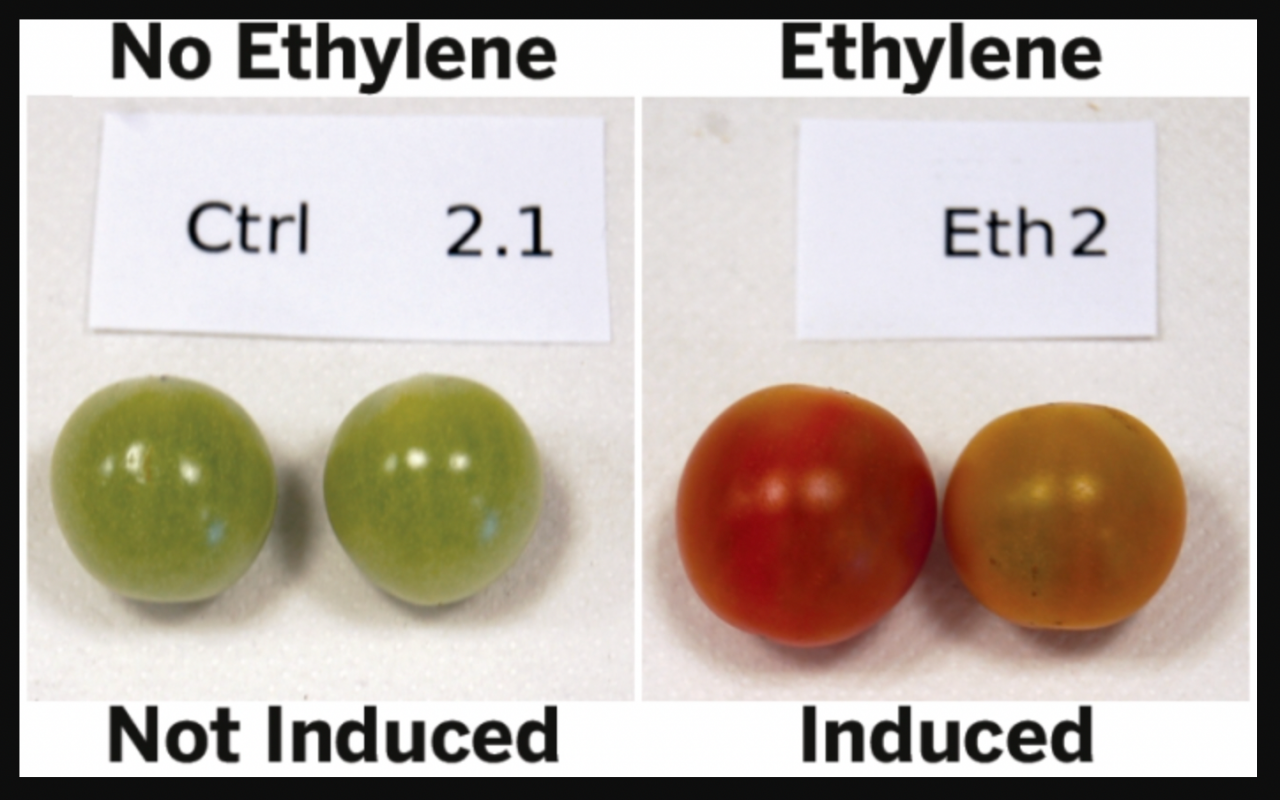

Ethylene gas plays a crucial role in the ripening process of tomatoes. It triggers a series of physiological and biochemical changes that transform unripe, green tomatoes into ripe, red ones.

When exposed to ethylene gas, tomatoes undergo a cascade of biochemical reactions that break down chlorophyll, the green pigment responsible for their unripe appearance. Simultaneously, the production of carotenoids, the pigments responsible for the red color of ripe tomatoes, increases.

These changes result in the characteristic color change associated with tomato ripening.

Ethylene gas also influences the texture, flavor, and aroma of tomatoes. It promotes the softening of the fruit by breaking down cell walls and increasing the production of pectin, a substance that gives tomatoes their characteristic texture. Additionally, ethylene gas enhances the production of sugars and volatile compounds, contributing to the sweet taste and distinctive aroma of ripe tomatoes.

Methods of Ethylene Gas Application

There are several methods used to apply ethylene gas to tomatoes for ripening purposes.

- Direct Application:Ethylene gas can be directly applied to tomatoes using specialized equipment that generates and releases the gas. This method provides precise control over the amount of ethylene applied and is often used in commercial settings.

- Ethylene-Releasing Chemicals:Certain chemicals, such as ethephon, release ethylene gas when applied to tomatoes. These chemicals are typically applied as a spray or drench and offer a more gradual release of ethylene compared to direct application.

- Modified Atmosphere Packaging:Tomatoes can be packaged in a controlled atmosphere containing elevated levels of ethylene gas. This method allows for a more uniform distribution of ethylene and is often used during transportation and storage.

Commercial Applications

Ethylene gas has significant commercial applications in the tomato industry.

- Controlled Ripening:Ethylene gas is widely used to control the ripening of tomatoes, allowing growers and distributors to meet market demand and extend the shelf life of the fruit.

- Uniform Ripening:By applying ethylene gas, growers can achieve uniform ripening of tomatoes, ensuring a consistent quality and appearance.

- Reduced Postharvest Losses:Controlled ripening using ethylene gas helps reduce postharvest losses by preventing over-ripening and spoilage, leading to increased profitability for growers and distributors.

Regulations and Safety Measures: Ethylene Gas To Tomatoes Nyt

To ensure the safe and responsible use of ethylene gas in the tomato industry, various regulations and safety measures are in place.

In legal proceedings, a motion to vacate is a formal request to a court to overturn or set aside a previous judgment or order. This motion is typically filed when there is evidence that the original judgment was based on fraud, mistake, or newly discovered evidence that could have changed the outcome of the case.

- Maximum Residue Limits:Regulatory agencies establish maximum residue limits for ethylene gas in tomatoes to minimize potential health risks to consumers.

- Good Agricultural Practices:Growers are required to follow good agricultural practices, including proper ventilation and protective gear, when applying ethylene gas to tomatoes.

- Monitoring and Enforcement:Government agencies and industry organizations monitor and enforce regulations to ensure compliance and protect public health.

Research and Future Directions

Ongoing research efforts aim to improve the understanding of ethylene gas and its effects on tomato ripening.

- Optimizing Ethylene Application:Research is focused on optimizing ethylene application methods to achieve optimal ripening while minimizing potential health risks.

- Ethylene Biosynthesis and Metabolism:Scientists are studying the biosynthesis and metabolism of ethylene in tomatoes to gain insights into the molecular mechanisms underlying ripening.

- Alternative Ripening Technologies:Researchers are exploring alternative ripening technologies that reduce or eliminate the use of ethylene gas, potentially addressing health concerns and environmental impacts.

Final Wrap-Up

As we continue to unravel the intricate relationship between ethylene gas and tomato ripening, new avenues for research and innovation emerge. Scientists are exploring the potential of ethylene gas in extending the shelf life of tomatoes, reducing post-harvest losses, and enhancing their nutritional value.

The future holds exciting possibilities for harnessing the power of ethylene gas to improve tomato production, distribution, and consumption.

In the realm of tomato ripening, ethylene gas reigns supreme, orchestrating a symphony of changes that bring this beloved fruit to life. Its influence extends beyond the tomato itself, impacting the livelihoods of growers, the choices of consumers, and the overall dynamics of the tomato industry.

As we delve deeper into the world of ethylene gas and tomato ripening, we uncover a story of science, innovation, and the pursuit of culinary perfection.